What is exposed concrete?

Exposed concrete is a new type of concrete and its main application is in building facades. The use of this material in the facade of the building creates a modern and beautiful view that has its own beauty.

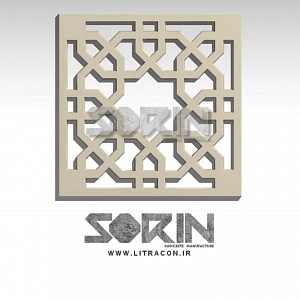

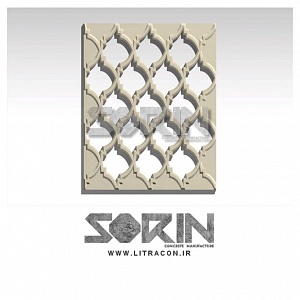

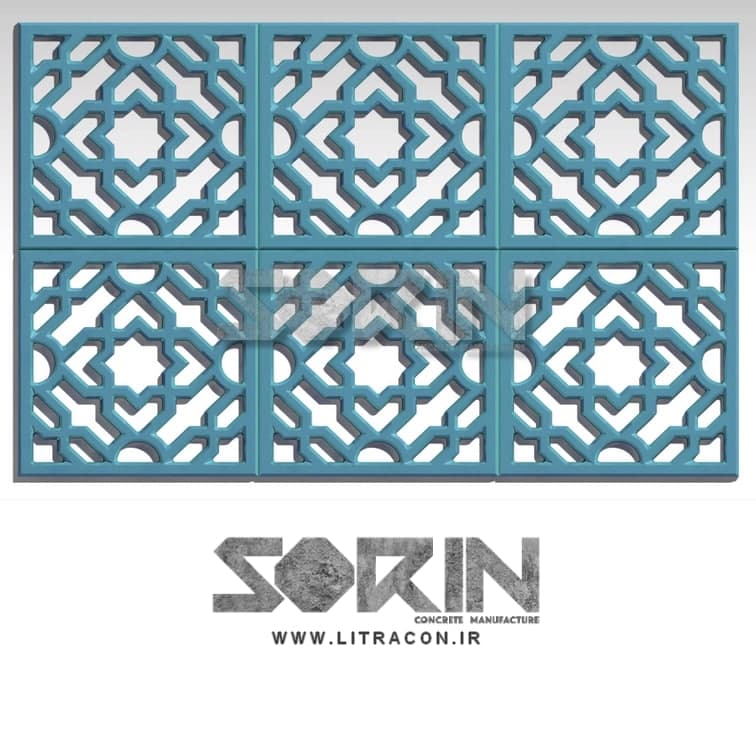

Exposed concrete is a prefabricated concrete panel that is used on the final surface of floor or exterior and interior facades. As a matter of fact, concrete is considered as one of the most widely utilized materials in the construction industry due to its ease of production, long life and resistance to climate conditions. Exposed concrete, due to the high variety of designs and colors and the ability to produce in different dimensions, allows designers, engineers and employers interested in modern architecture to have a wide selection for their project.

Applications of exposed concrete

- Covering exterior facade of the building

- Interior facade and decoration

- Exposed concrete walls

- Landscaping

- Floor and stair covering

Exposed concrete landmark features

- Sound insulation

- Insulation

- Variety of colors of different types of concrete

- Fire and moisture resistance

- Increasing project speed

- Adaptation to weather conditions

- Ability to execute in different dimensions

- Long life

- Being environmentally friendly

Standard dimensions of exposed concrete panels:

Rectangular pieces: 50 * 100, 60 * 120, 70 * 140, 80 * 160, 100 * 200, 200 * 400

Square pieces: 50 * 50, 60 * 60, 80 * 80, 100 * 100

Customized dimensions: panel in desired dimensions, L-shaped pieces, U-shaped pieces, multifaceted pieces.